Entering an Inventory Adjustment

Foam Items in Inventory

In JobPro Inventory v2.0, you can set up your foam items to be tracked through inventory. By using this, you will be able to easily transfer, pour up and monitor usage of your Spray Foam and Insulation products at a greater level. We will walk you through the set up for foam items with this guide. Make sure that you have your warehouses set up correctly before you start your inventory, and that goes for both foam and non-foam items.

The Nature of Foam in JobPro Inventory 2.0

Spray Foam Drums are viewed in inventory as serialized items with associated volumes. On the Item Page Pricing Tab, the Inventory Costing is SPID indicating the item is serialized. Foam Drums are added to inventory via two processes: Order and Receive items from Stock order or perform Inventory Adjustment. Both processes will require you to enter the serial number for the drum and its associated volume. Drum volume is stored as sets. For example, 1 set = 1 full drum, .5 set = ½ drum.

Setting up Foam Items

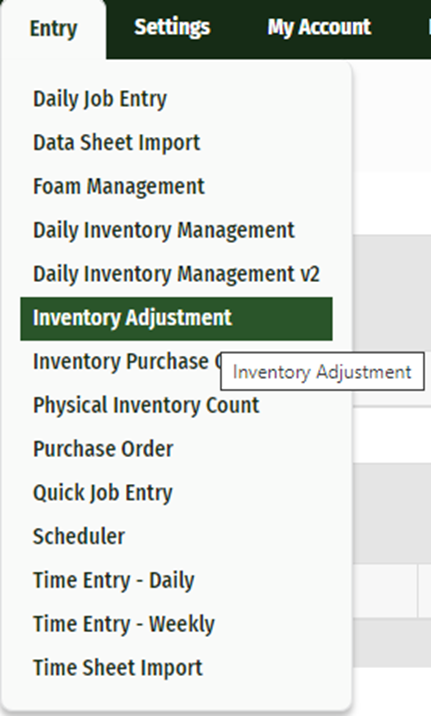

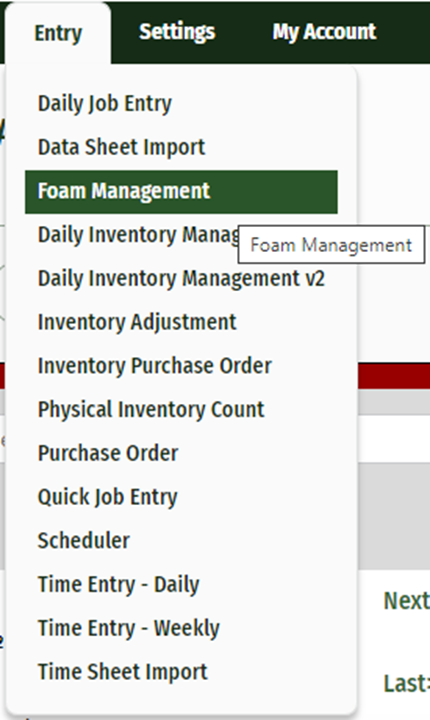

In order to get your foam items into your Warehouse, go to the Entry drop down and select Inventory Adjustment.

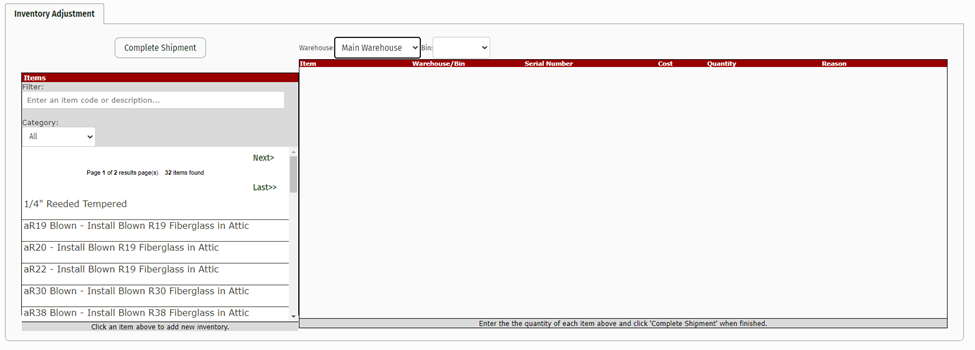

If you have more than one warehouse set up, you will need to make sure that the Warehouse on the Inventory adjustment screen is set to the correct warehouse.

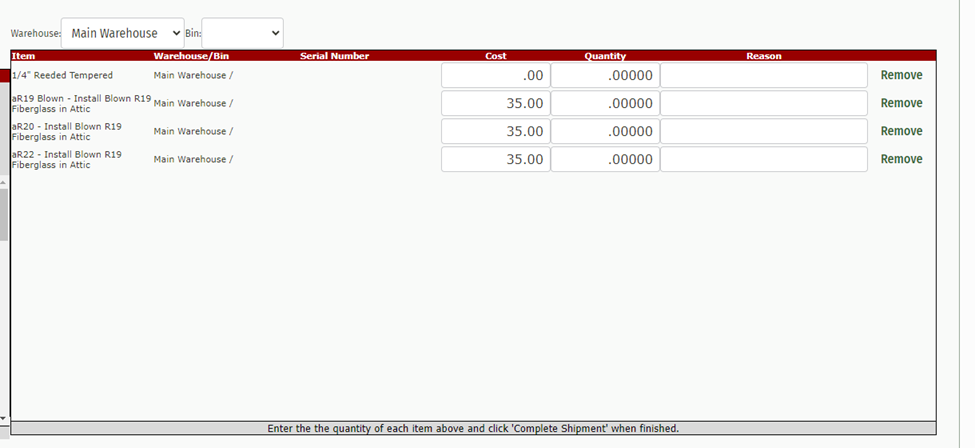

Once you have selected the correct warehouse, you can start adding your items. The picture below gives you an example of a few different drums and serial numbers for the same item. Since, this is your first time entering these foam items into inventory you will need to give a reason why you are adjusting the inventory.

Once your drums are entered, hit Complete Shipment.

These items should now be in your warehouse for use. To view and manage the items, go to the Entry dropdown and select Foam Management.

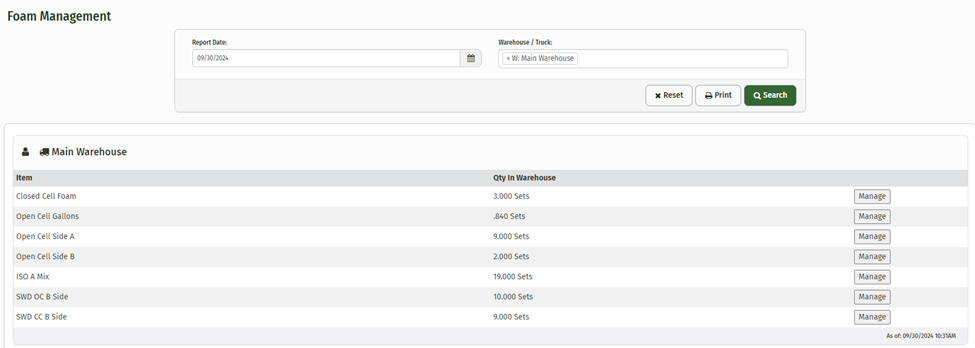

Once you’ve arrived, you’ll need to select the Warehouse and hit search. Here, you can see how many sets you have of each type of foam you use within your inventory. This is important for the person who is managing your foam inventory, because they will be able to see where the foam is being used from either a Warehouse or a truck and manage it before, during and after a job. Click Manage.

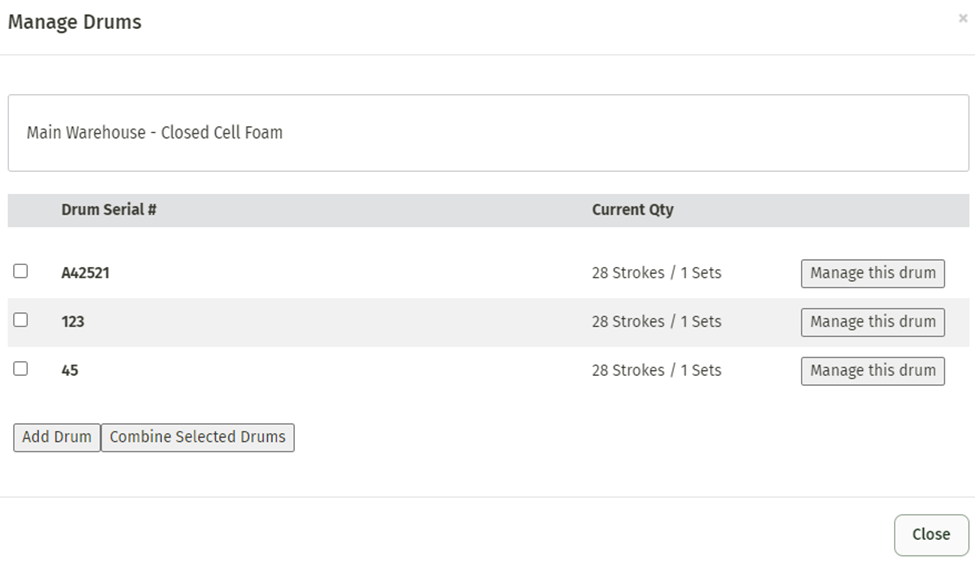

This brings up how much you have in each drum that you added into inventory. Click Manage this drum.

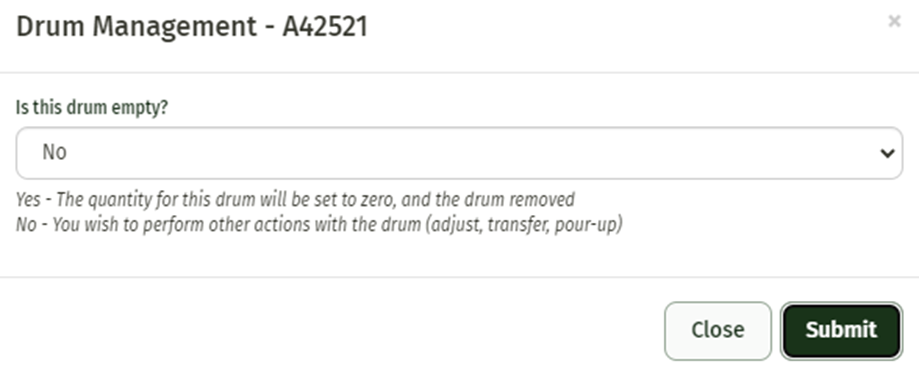

This is going to bring up another popup that will ask if this drum is empty or not. If you click yes, the drum will be set to 0 and removed. If you click no, you can perform more actions with this drum.

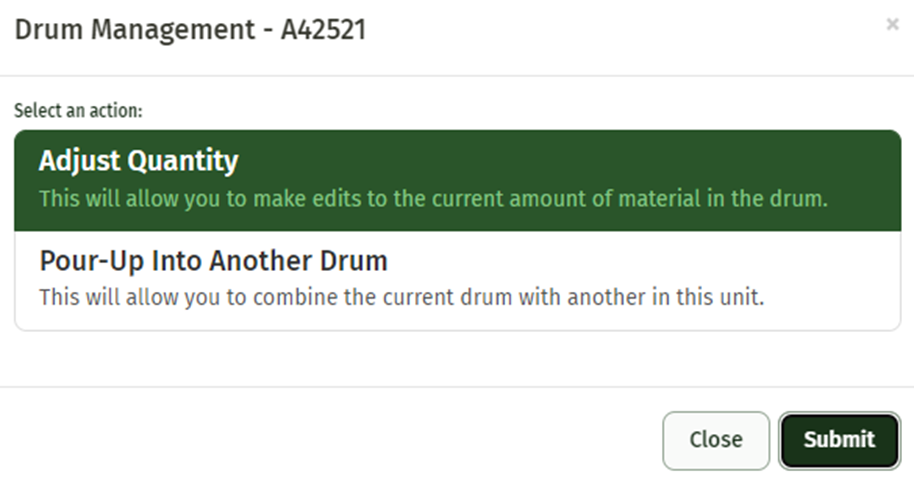

When clicking no, it gives you the option to Adjust the quantity of the drum or Pour-up Into Another Drum. Pouring up into another drum allows you to combine drums that may not have a full set (1) within them. It is important to note, you cannot have more than 1 in any set.

That pretty much sums up the setting up portion of foam. Now we will move to using foam items.