Using Foam Item Inventory on a Job

Now that you have entered your foam items into inventory, they are ready for use within a job. You will create a bid, per usual, then create the job with the required items. The bidding process is no different with inventory turned on in the JobPro System. Follow the steps below to properly use our Inventory setup.

Loading Material

Before processing your foam inventory items on the job processing tab, you must first load your inventory on your equipment through the Daily Inventory Management Screen. For an in depth look at this feature click the link below:

Using Foam on a Job

As previously stated, in order to use foam from inventory on a job your equipment must be set up correctly. If you followed the steps above, you should be ready to use foam. We will walk you through the steps here.

To enter the foam material navigate to the 'Job Processing Tab

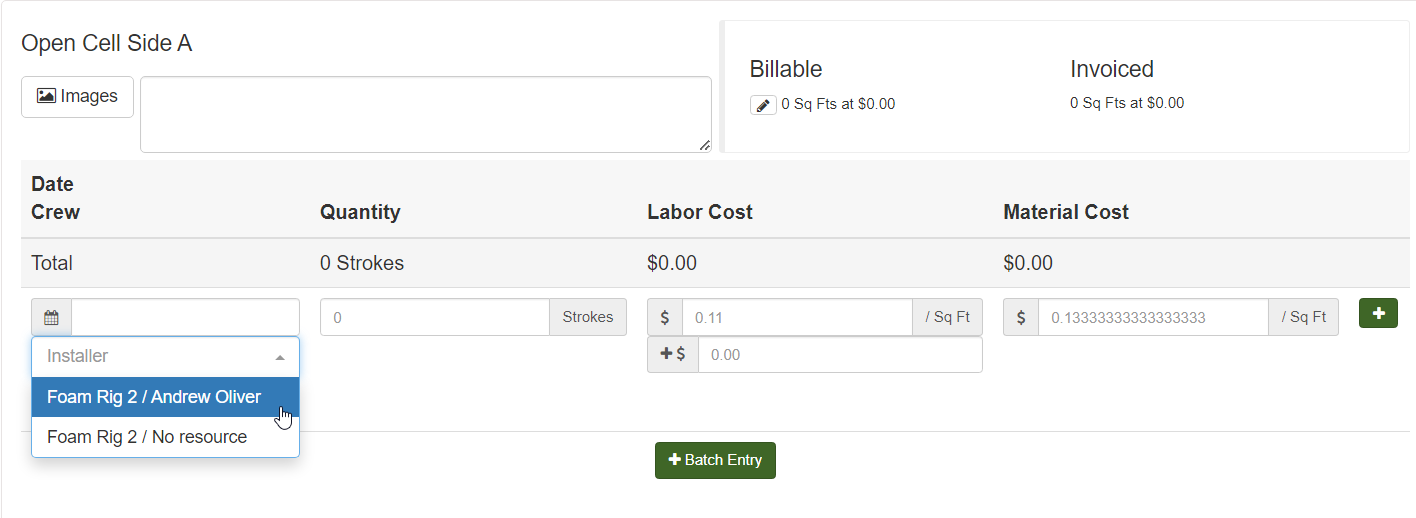

On the item you would like to enter. Select Installer underneath the item you are planning to use and you will see the equipment that is scheduled to the job.

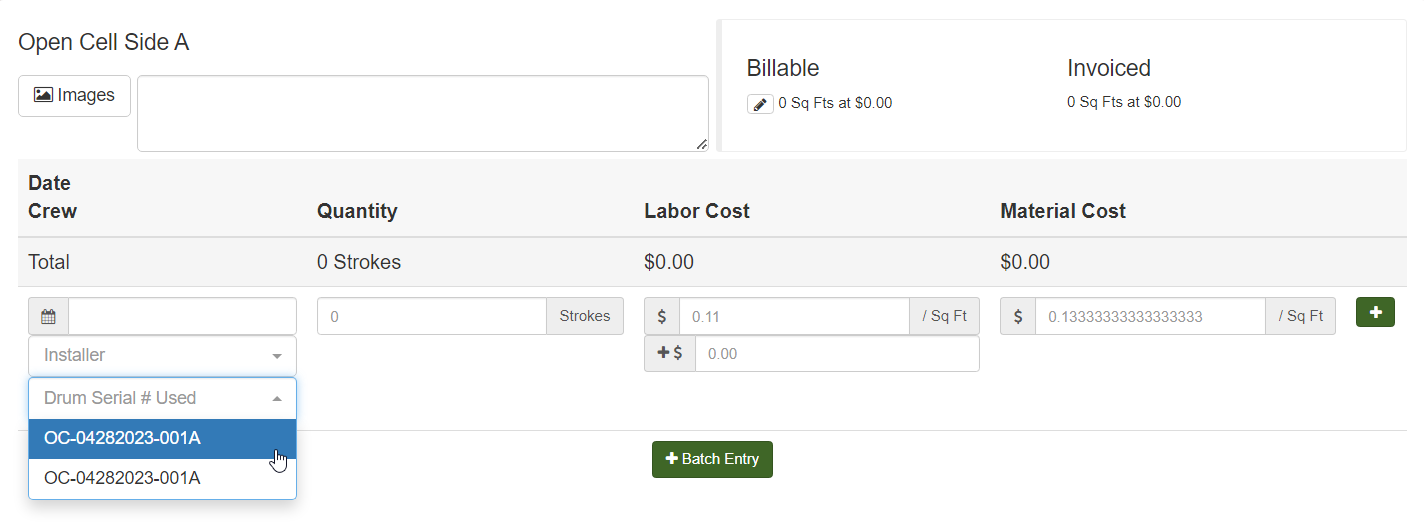

Once the installer is in place, you will select the Drum Serial # Used. These drums will be the only drums that you placed on this truck in the Foam Management page.

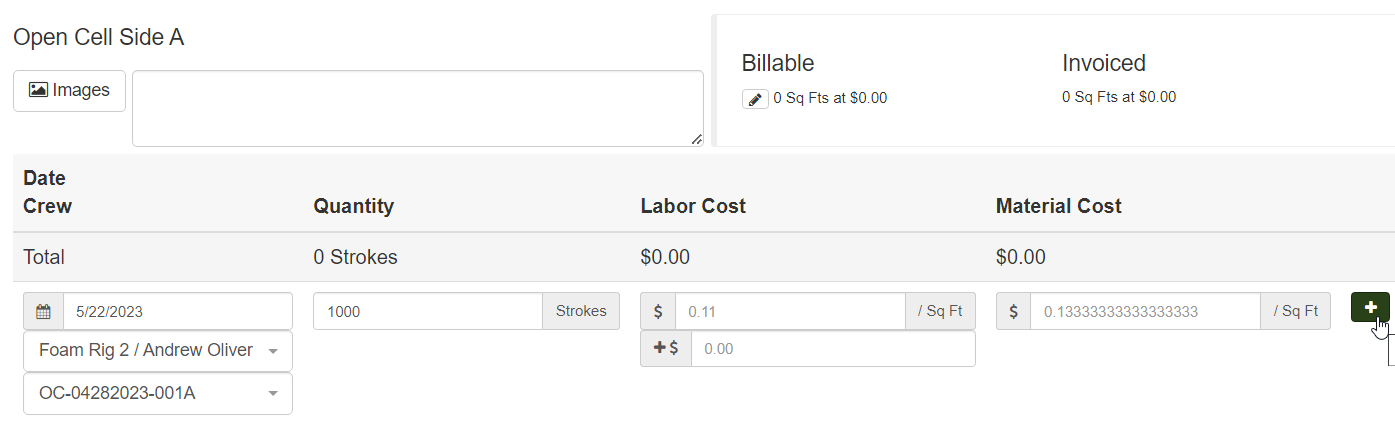

Insert the amount of foam you used (strokes, inches, etc.) and the date you used it and click the plus icon.

Managing Drum Inventory

Once you have finished entering all of your actual material usage, you will need to navigate back to the Daily Inventory Management screen.

From here there are two ways you can manage your Foam drums.

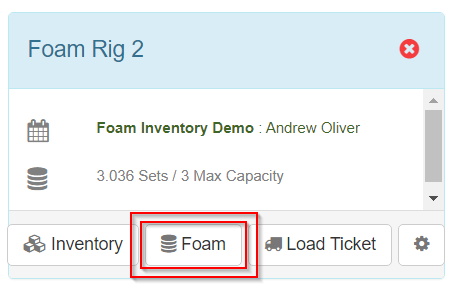

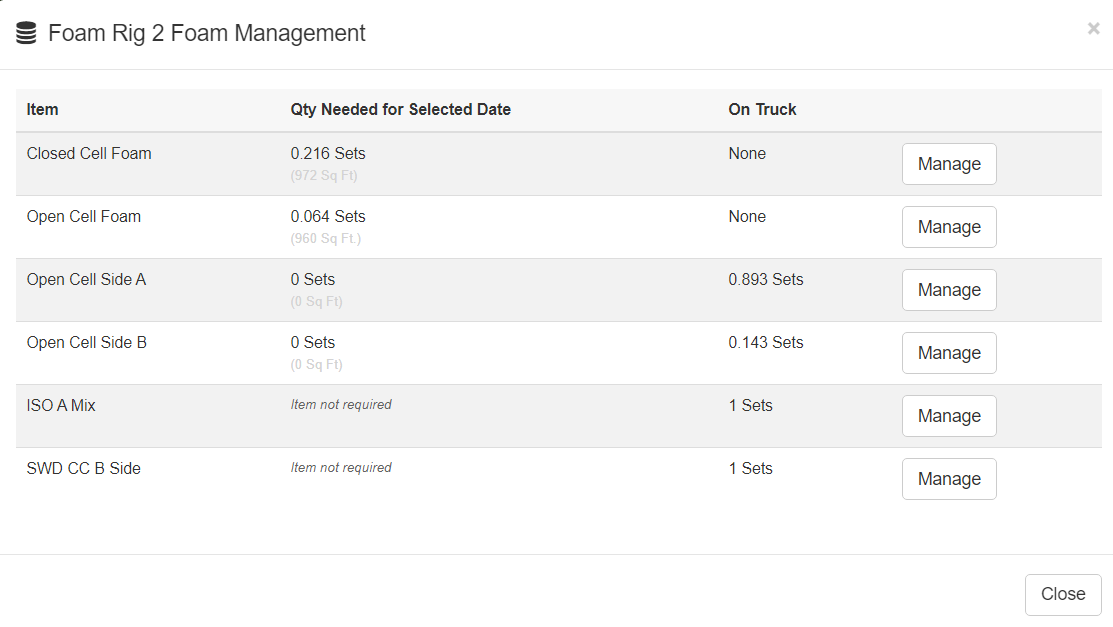

The first option is to click the ‘Foam’ button on the equipment where your foam drums are located

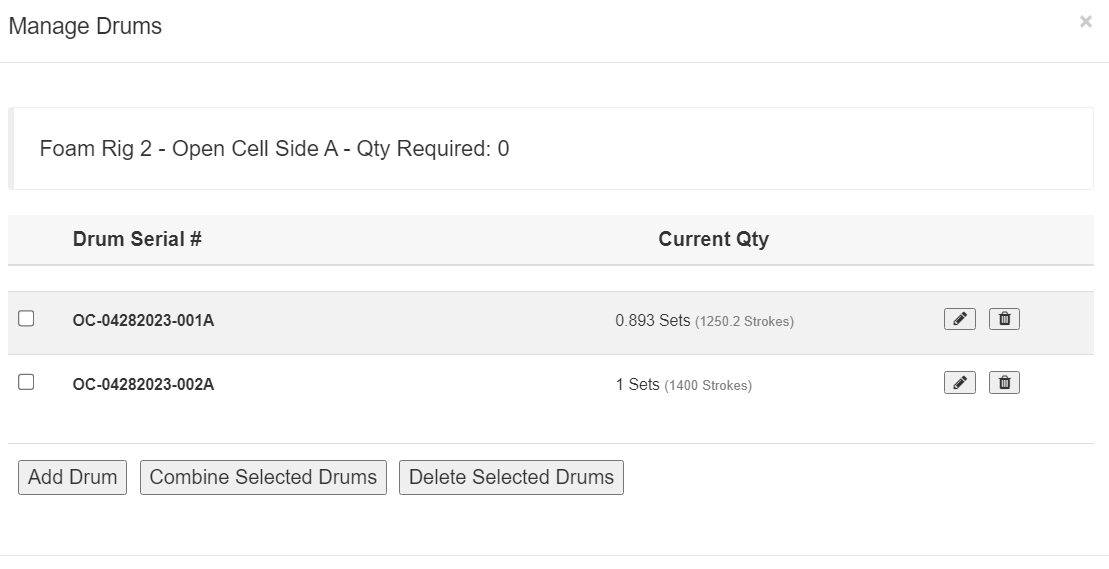

This will open a pop-up window where you can manage your drums

Simply select ‘Manage’ on the drum you’d like to edit. From there you can combine or delete the selected drums, or choose to edit the individual drum by clicking the pencil icon to the right of the drum you need.

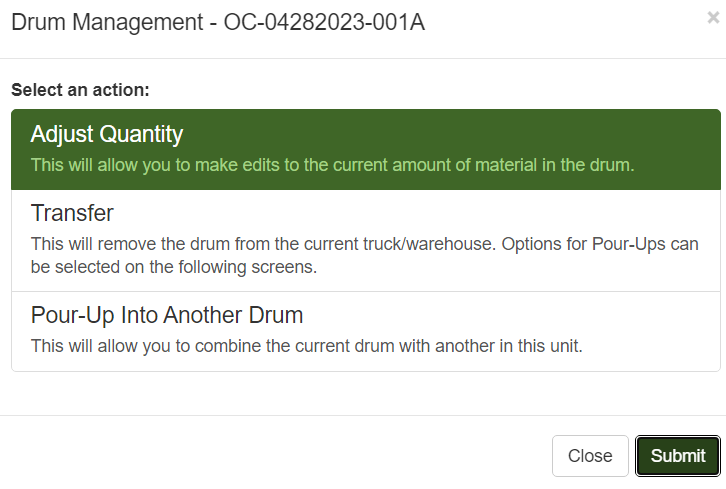

When you click the pencil icon, a pop-up window will appear that gives you three options for what you can do with this drum. You can adjust the quantity, transfer to another truck or warehouse, or pour up into another drum

A few other notes on foam usage and drums.

Once a drum is depleted (put to zero) it is removed from your inventory.

A drum cannot go over 1 set.

Drums will always need to be serialized to track for inventory.

Keeping your trucks constantly at full capacity will help with transfers and pour-ups.

Foam Management will need to be constantly updated for new drums and serial numbers.